Description

HM-60 is a high strength, high modulus unidirectional carbon fiber fabric.

It is laminated with epoxy resin adhesive to form a carbon fiber reinforced polymer lamination (CFRP) used in structural strengthening.

Carbon fiber not only has high strength and high elastic modulus, but also possesses the characteristics of light self- weight and high durability.

First, it was adopted for the aerospace and auto industry applications, followed by the sporting goods and machinery industries.

In recent years, as the substitute of reinforcing materials in concrete structures, it has been widely used for seismic strengthening of highway structures, railway and bridge piers, tunnels, and buildings.

Currently, it is being explored for structural modifications of highway bridges for increase in traffic volume.

Application Range

- Load increase : Increase in traffic weight and volume on bridges., Increase in loads in commercial buildings ., Installation of heavy equipment in industrial facilities., Increase of vibration in structures.,

- Improve Structural : Condition Reduce deformations., Reduce stresses in existing structural elements., Limit or arrest crack propagation.,

- Seismic Retrofitting : Columns wrapping reinforcement for improving ductility and shear strength., Masonry walls reinforcement for improving out-of-plane bending and in-plane shear strengths., Beam and slab reinforcement

- Change Structural System (Structural Alterations) : Removal of walls or columns., Removal of slab sections for openings.,

- Aging and Damaged Structures : Aging of old deteriorated construction materials., Corrosion of steel bars in concrete., Vehicles collusion impact on structures (impact damage)

- Design or Construction Errors : Lack of adequate well-detailed reinforcing bars., Inadequate member cross section., Substandard concrete material strength

Product Characteristic

- Light self-weight : Allows operation in a narrow and tight spaces; Minimal impact on the normal use of the structure during construction; Adds almost no additional weight to the existing structure.

- High strength, high modulus: Very effective in flexural strengthening in the form of straight sheets, shear strengthening in the form of closed loop wrapping, U-shaped and side bonding; Increase ductility and strength of circular columns in the form of transverse wrapping; Restoration of various complex shape structural elements.

- Wide application range: Suitable for surface of various structural components: Beams, columns, ventilation tubes, pipes, walls, etc.; It could be used on various types of structural components and systems, e.g. concrete structures, masonry structures, wood structures, steel structures, and many other structural elements and systems.

- Anticorrosion : Anti-acid, alkali and other chemical corrosion and resistance to severe environments.

- Long storage life : Allows for long operation projects and extended deadlines.

- High temperature resistance, limited creep resistance under high permanent loads, high corrosion resistance and excellent seismic strengthening system.

Horse Advantage

- Aviation Grade Yarn : Produced from high-quality international aviation grade yarn, every carbon fiber yarn length kept over 5000 meters to ensure the continuity of the carbon fiber fabrics without damage raw fiber.

- World Leading Production Line : Germany imported intelligent production line. Point to point active wefting insertion. No damage or break of filament during the whole production process.

- Patented Tension Controling System : Independently developed constant tension system, ensures every bunch of raw fiber is kept under constant tension. With low dispersion, high strength, stable properties, the qualification rate by national authority testing organization is 100%.

- Less Epoxy Adhesive Usage : The carbon fiber fabric is woven evenly and smooth, moderate soft, good suitability with the impregnated adhesive, which are easy to impregnate. The total adhesive usage is just 15%, less than products by other manufacturers, and the hollow issues maintained at 80% less than other products.

- Large Output and Timely Delivery : Annual production capacity of quality carbon fiber fabric is 5 million square meters, while maintaining a daily stock of over 100,000 square meter to meet any project’s demands, around the world.

Technical Parameters

- Model : HM-60

- Appreance : Black fabric

- Length : 50

- Width : Regular width is 100mm, 150mm, 200mm, 250mm, 300mm, 500mm, other width can be customized.

- Shelf Life : 10 years

- Storage Conditions : Store in dry conditions at 40°F to 95°F (4°C to 35°C)

- Braiding : 0° (Unidirectional)

- Areal Weight : 600g/m²

- Package : This product uses carton package. When the width is 100mm, 200mm, 300mm, the total area of carbon fiber per case is 30m’; when the width is 250mm, 500mm, the total area of carbon fiber per case is 25m².

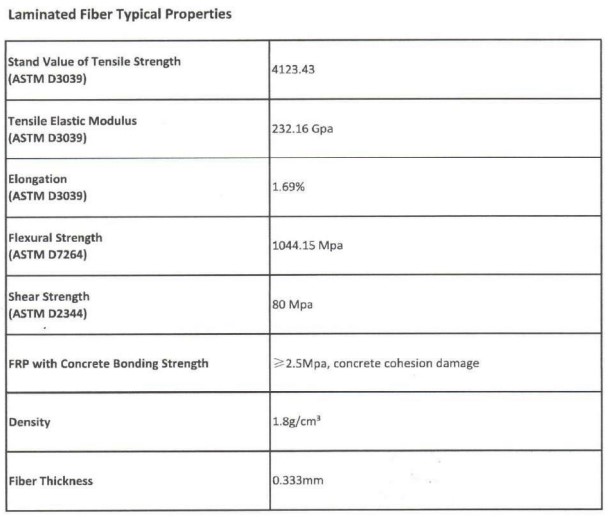

Typical Fiber Properties

Surface Preparing: Remove the coating of concrete surface with grinder. Polishing the Surface. If there is angular, grinder it into round.

Surface Preparing: Remove the coating of concrete surface with grinder. Polishing the Surface. If there is angular, grinder it into round.- Setting out: Get the concrete surface clean and keep it dry, then setting out.

- Apply Primer: Apply primer adhesive onto the surface of the concrete.

- Apply Putty/Leveling: Apply putty for repairing and leveling if needed.

- Fabric Cutting: Cut carbon fiber fabric into sizes as designed.

- Preparing the impregnation adhesive: Weight and mixing adhesive according to ratio. Stirring the adhesive until the color is even. Avoid air bubble in this process

- Applying Impregnation Adhesive: Apply impregnation adhesive when primer adhesive is touch dry. (If primer is not required, impregnated adhesive can be applied directly.)

- Apply carbon fiber fabric: Apply carbon fiber fabric onto the concrete surface as designed. Leveling the surface from one end to another.

- Check Gap or Bubble: Apply impregnation carbon fiber adhesive again. Make sure the adhesive impregnate fully into the fabric. The surface flat and no air bubble. Repeat above process from cutting carbon fiber if applying two or more layers.

Transportation and Storage

This product should be stored in a dry, cool and well- ventilated environment. It should not be exposed to rain, or subjected to impact by sharp objects.

During transportation and storage, carbon fiber materials shall not be squeezed or compressed, so as to avoid carbon fiber damage, and shall not be exposed to direct sunlight and/or rain.

Safety Measures

The construction workers should take all necessary protective measures (such as wearing masks, gloves, goggles, etc.). Safety measures should be taken on site to keep the site clean and prevent fire hazards.

Carbon fiber is conductive, safety measures should be taken to prevent electric shocks.

Carbon fiber sheets should not be bent during transportation, handling, and cutting process.