Description

Carbon fiber adhesive includes carbon fiber primer HM- 180, carbon fiber leveling adhesive HM-120ML, carbon fiber impregnated adhesive HM-180C3P.

- Primer HM-180, used for improving the properties of the concrete surface, which is in direct contact with the carbon fiber system.

- Leveling Adhesive HM-180CE, used for leveling and repairing physical defect on the concrete surface of the existing structure.

- Impregnating Adhesive HM-180C3P, used for impregnating carbon fibers and bonding the carbon fiber fabric to concrete surface.

Aplication Range

This product is high performance epoxy adhesive, which can be used for the effective penetration bonding to many substrate materials such as concrete, steel material, ceramic, stone, wood component, and many fiber fabrics, e.g. carbon fiber, glass fiber, basalt fiber, and aramid fiber.

It is mainly used for the strengthening and reinforcement of structural systems.

Product Characteristics

- Primer HM-180: Low viscosity, good liquidity, strong penetration ability, can well infiltrate and bond the cracks and defects on the concrete surface.

- Leveling adhesive HM-180CE: Good thixotropic properties, easy to apply, excellent for filling small holes and chipped-out concrete, and level the surface of the concrete.

- Carbon fiber impregnating adhesive IIM-180C3P: Low viscosity, good impregnating properties, can well infiltrate the carbon fiber fabrics, good thixotropic properties makes it easy to apply.

- Compatibility: Good compatibility with carbon fibers.

- Anticorrosion: Excellent durable performance, corrosion resistance, humidity and moisture resistance, and chemical corrosion resistance.

- High property: After curing, it has good physical properties, good toughness and elastic properties.

Packing

The A and B components of this product are packed in separate metal containers. Group A is 20kg/container and Group B is 10kg/container.

Shelf Life

When stored correctly, the shelf life will be at least 18 months from the date of manufacture.

Horse Advantage

- Nano Material : Use of the advanced nano material technology to improve the product’s overall performance, and ensure the thixotropic and other properties are better so fibers could be easily coated.

- Modified Epoxy : Use of low viscosity two components A style modified epoxy resin, and adjusted polarity of the functional group to improve penetrability.

- Improved Formula : Adoption of very advanced formula, which makes the adhesive coupling-reaction takes place with different substrates, the bond strength improved by at least 18%, along with achieving higher durability.

- Less Usage : No organic volatile, no filler, good suitability. Compared with other products, it saves at least 15% in usage.

- Production : Equipment Advanced high speed dual planetary power mixing equipment, which results in the raw materials being mixed evenly. Meanwhile, the use vacuum treatment ensures no air bubble created, which extends the shelf life of the product and improves the stability of its performance.

- Test Reports : Product passed several safety tests, e.g. Non-toxic testing, Horizontal firing test, Non ethanediamine test, Acute oral toxicity test etc.

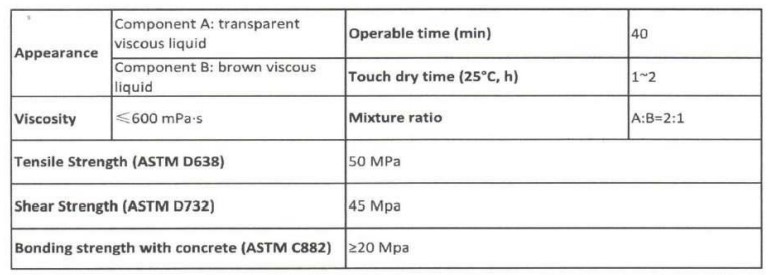

Premier HM-180

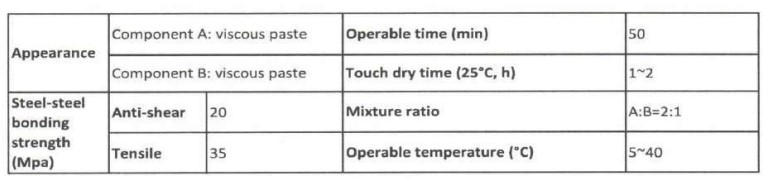

Leaveling Adhesive HM-180CE

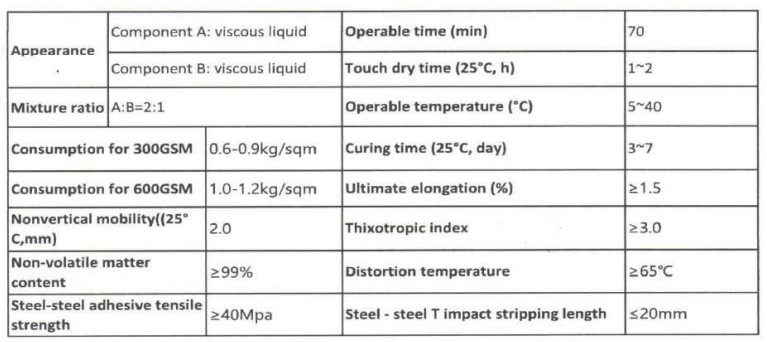

Carbon Fiber Impregnated Adhesive HM-180C3P

- Surface Preparing: Remove the coating of concrete surface with grinder. Polishing the Surface. If there is angular, grinder it into round.

- Setting out: Get the concrete surface clean and keep it dry, then setting out.

- Apply Primer: Apply primer adhesive onto the surface of the concrete.

- Apply Putty/Leveling: Apply putty for repairing and leveling if needed.

- Fabric Cutting: Cut carbon fiber fabric into sizes as designed.

- Preparing the impregnation adhesive: Weight and mixing adhesive according to ratio. Stirring the adhesive until the color is even. Avoid air bubble in this process.

- Applying Impregnation Adhesive: Apply impregnation adhesive when primer adhesive is touch dry. (If primer is not required, impregnated adhesive can be applied directly.)

- Apply carbon fiber fabric: Apply carbon fiber fabric onto the concrete surface as designed. Leveling the surface from one end to another.

- Check Gap or Bubble: Apply impregnation carbon fiber adhesive again. Make sure the adhesive impregnate fully into the fabric. The surface flat and no air bubble. Repeat above process from cutting carbon fiber if applying two or more layers,

Transportation and Storage

This product should be kept sealed and stored in a dry and clean storage space of ambient temperature between -5 oC and 40 oC. In order to prevent damage, do not store outdoor under direct sunlight or under direct rain.

A & B components should be kept separately. Storage period is 12 months at room temperature (25 oC); if it is stored for more than 12 months, it should be tested. If the physical and mechanical properties after 12 months meet the standard requirements, then it could be used;

These products are not inflammable, explosive, toxic, or dangerous cargoes. They could be transported with general transportation cargo. The epoxy containers should not be damaged, exposed to direct sunlight or rain, and should not be tilted or stored upside-down during transportation.

Points for Attention

Mix proper amount of adhesive at one time, use up within the applicable period, do not use the adhesive if it is beyond the applicable period;

If components A and B of the adhesive are not used up, they should be covered and sealed. They should not be exposed to air for a long time;

The construction workers should take all necessary safety measures (such as wearing masks, gloves, goggles, etc.), and maintain fire prevention measures, as well as keeping the site clean;

If the adhesive accidentally got in touch the skin and cloths, acetone can be used to wipe it at once, followed by a great deal of clear water;

If accidentally swallowed or splashed into the eyes, please seek immediate medical service.