Characteristics

–

Materials

Zinc Alloy Anodes are cast from high grade zinc alloy to ensure an even corrosion pattern, reliable electrical effeciency and long working life

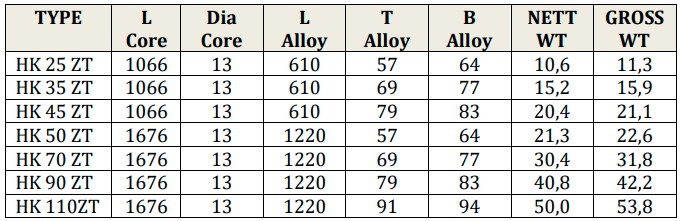

Product Range

Zinc Alloy anodes are cast to U.S. Military specifications U.S.MIL A18001 K and yield 780 amphere hours per kilogram of alloy with a solution potential of -1100mV as measured against a silver chloride reference cell.

The standard HAKA range of zinc alloy anodes is listed overleaf. However HAKA has the facility of designing and producing anodes to meet any individual requirement and make their own moulds to do so. Thereby, they ensure both the optimum solution to any particular problem and total control over the quality of the finished anodes.

Applications

Zinc Alloy anodes are particularly suitable for ballast tanks and hull of ship, jetties and subsea pipeline applications in bracelet configuration. Zinc alloy anode is not suitable in high temperature environment of 50 C and above.

Chemical Composition

U.S.-Mil-A-18001 K

- Alumunium 0,01 – 0,50 %

- Cadnium 0,025 – 0,07 %

Iron 0,005 % max - Copper 0,005 % max

- Lead 0,006 % max

- Other 0.10 % max

- Zinc Balance

Electrochemical Properties :

- Nominal Potential -1,050 V Ag/AgCl

- Nominal Capacity 780 AH/Kg

ZINC ALLOY FOR HULL

BOLTED HULL ANODES

ZINC ANODE FOR TANK